B2B Automotive & Aviation Upholstery

Exlusive upholstery production for premium vehicles, restomods and aviation sector.

Get a quote now

B2B Automotive & Aviation Upholstery

Exlusive upholstery production for premium vehicles, restomods and aviation sector.

Get a quote now

Trusted Partner

Our facilities have been awarded European certificates, which is a guarantee of product safety, top quality, and repeatability of series production. Our products undergo strict quality control procedures, such as seat and dashboard airbag deployment tests.

Your design

We will execute any interior upholstery project using any material with your branding.

Quick quote

We provide a quote within one business day.

Know-how

Over 15 years of experience. We have our own machinery and 60 skilled upholsterers.

Door-to-door shipping

We arrange delivery from the client and to the client. We ship finished products to every corner of the world and ensure the highest quality of logistics services.

Fast execution

We complete projects as quickly as possible.

Get a quote now

Automotive Upholstery Production

Carlex Design operates two parallel branches of business that form the foundation of its development.

The first branch is the ongoing development of its own line of cars under the prestigious Carlex brand. The second, equally important activity is the expansion of the factory producing exclusive leather upholstery, dedicated to clients in the Automotive and Aviation sectors.

AUTOMOTIVE & AVIATION

Many renowned car manufacturers from various continents have already expressed their trust in our brand. Our clients mainly include manufacturers of restomods, specialists in premium car tuning, and companies in the private aviation industry.

EXTENSIVE KNOW-HOW

Our specialization focuses on the production and supply of leather-upholstered components, where high quality and precision craftsmanship are key. Thanks to our passion for excellence, we provide services on a global scale.

EXCELLENT QUALITY

If you are looking for a trusted partner in the field of upholstery services with an emphasis on excellent quality, we warmly invite you to collaborate with us.

SERIAL UPHOLSTERY PRODUCTION

We offer serial production of both seat upholstery elements and comprehensive details, including dashboards, headliners, and hard panels.

EXPERT LOGISTICS SUPPORT

Our professional logistics department will handle all issues related to shipping, ensuring comprehensive service at every stage of cooperation.

Production Process

Read more about our production process

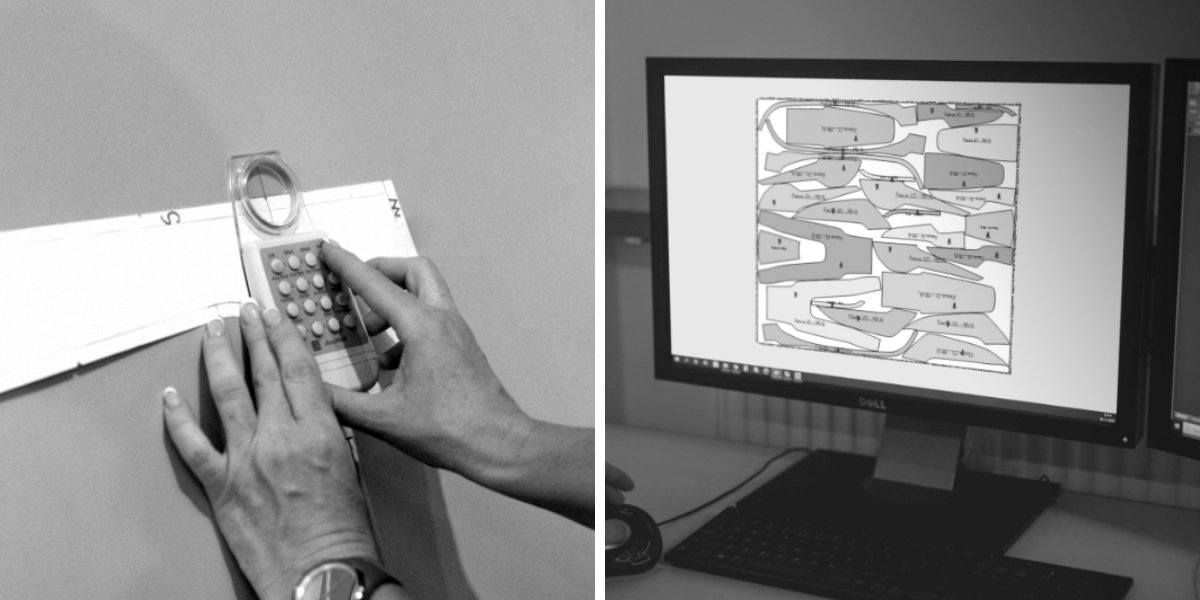

Upholstery Engineering and Templating

Our team of qualified upholstery engineers make the templates of the most complex upholstery patterns. The process is conducted in line with proper technical guidelines, e.g. the shape of the part or the upholstery cover mounting profiles. We use professional digitising boards facilitating the setting of parts and optimising the use of materials and production. The engineering process ends with the making of the prototype which undergoes a rigorous evaluation and approval stage in series production conditions.

Cutting Room

We use single layer machines for cutting upholstery parts, e.g. leather, and multiple layer machines for other materials, which allows for the optimisation of the costs and time of production.

The Comelz CZ Plus cutting machine is a state-of-the-art solution for precision cutting in the automotive industry, renowned for its efficiency and accuracy. Comelz is a world leader in fabric and leather cutting machines.

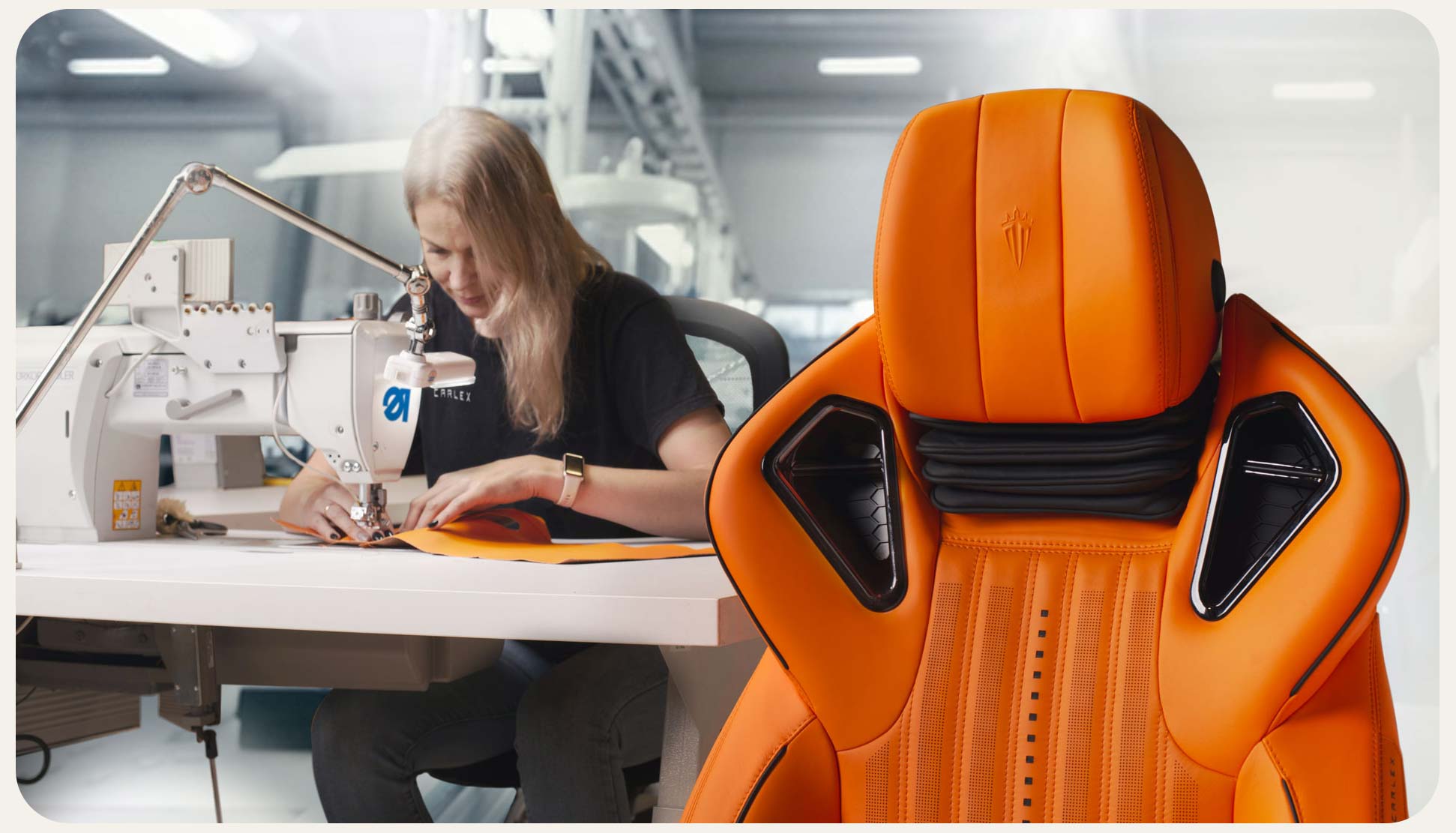

Sewing Room and Upholstery Room

The sewing process is based on a detailed instruction chart, comprising all the instructions necessary to make an upholstery cover. We have single needle and double needle flat-bed sewing machines, as well as post-bed sewing machines by Dürkopp Adler. The entire process undergoes inspection to eliminate any discrepancies as quickly as possible.

Refining and Decorating

Our state-of-the-art machines and tools allow for upholstery customisation in the form of bespoke embroidered motifs, laser-engraving, quilting, embossing, debossing, hot-stamping, and more.

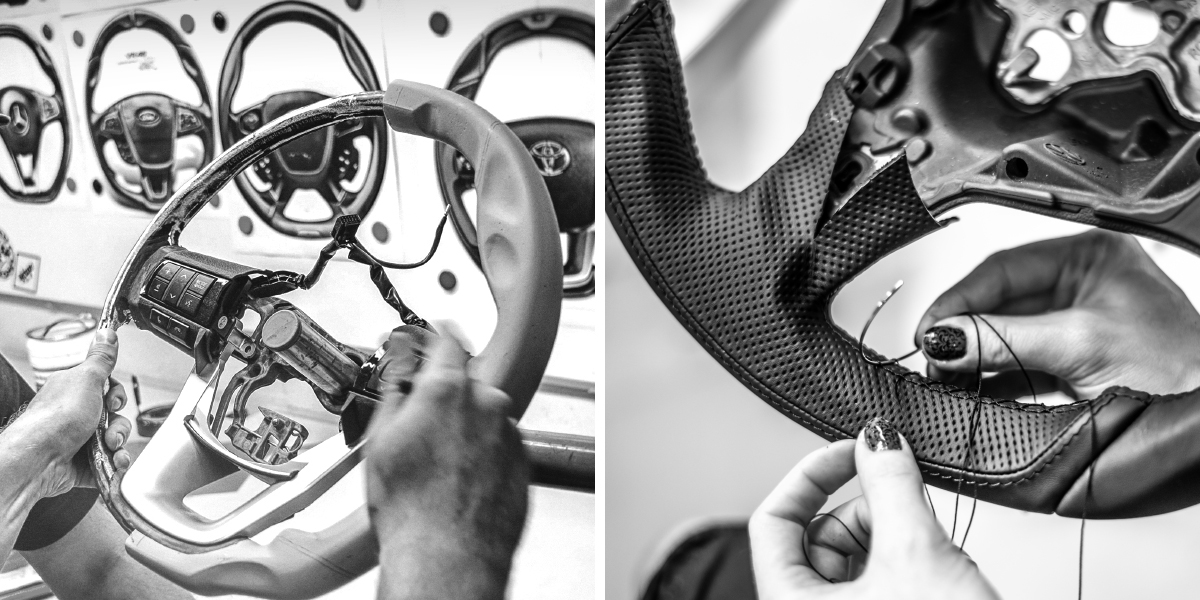

Steering Wheel Production

A new and aptly designed shape, a fancy look, and a perfect quality trim of the steering wheel ensure a comfortable and exciting driving experience. In Carlex Automotive, we design and make custom steering wheels with ergonomics principles and our customers’ needs in mind.

Quaility Inspection

Carlex Design implements stringent quality control measures and thorough inspections throughout their manufacturing process, ensuring every detail meets their exacting standards. Their commitment to precision and excellence results in impeccable craftsmanship and customer satisfaction.